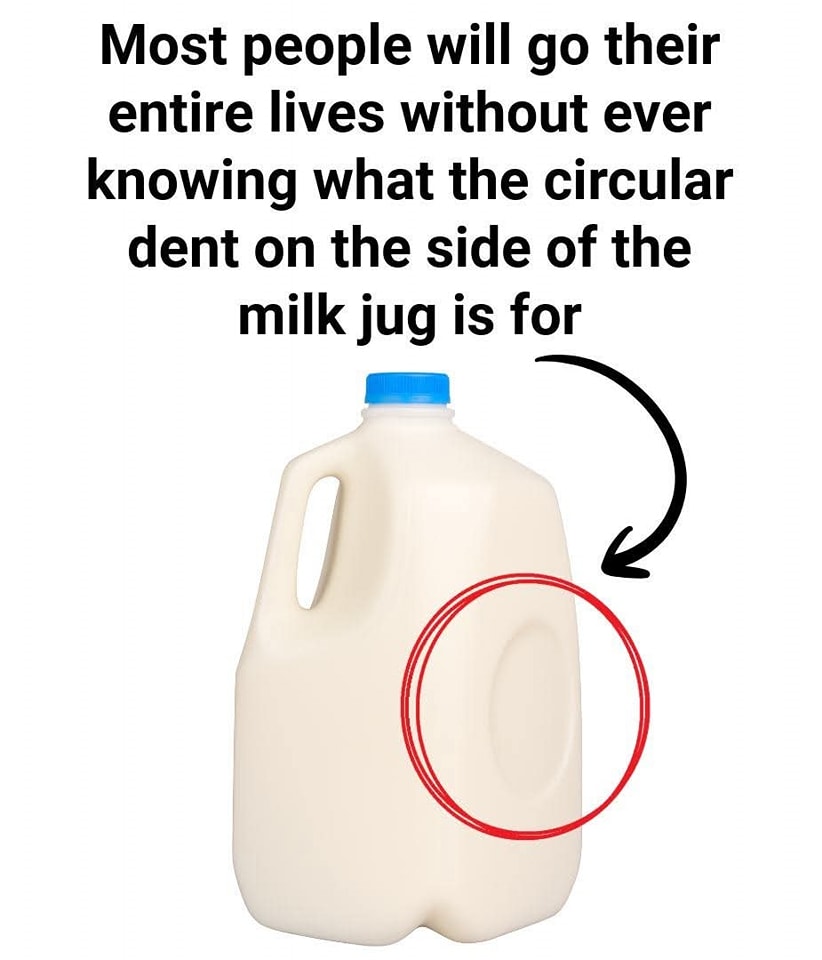

Let’s be honest—we’ve all stared at that strange little circular dent on the side of a plastic milk jug at some point, wondering what on earth it’s doing there. Perfectly round, tucked into the side like some kind of secret feature, it doesn’t seem to serve any obvious purpose.

Maybe you thought it was just a byproduct of the molding process or a harmless design quirk. But as it turns out, that dent isn’t just for show. It’s an intentional part of the design, and it actually plays several important roles that make your milk jug far more functional and efficient than you might expect. First, and perhaps most practically, that circular indent helps manage pressure. Milk, being a perishable liquid, is transported and stored at cold temperatures. But as milk jugs move from a warm delivery truck into a cold refrigerator, or even into a freezer, the liquid inside expands or contracts slightly depending on the temperature.

Without that small, flexible area in the jug’s wall, those changes in pressure could cause the jug to bulge, crack, or even explode. The dent gives the plastic a flexible zone that can expand outward as needed, acting almost like a built-in stress reliever. Think of it like the jug’s pressure valve—quietly doing its job to keep everything inside intact and under control. But there’s more. That dent also acts as a shock absorber. Have you ever dropped a full jug of milk? It’s not pretty. The impact can cause cracks, splits, and a catastrophic mess. The recessed design of the dent helps to redistribute the force of an impact, reducing the risk of breakage.

This is not just helpful for the average consumer at home—it’s a huge benefit during the transport and stocking process in grocery stores, where milk jugs are often stacked and jostled. Fewer broken jugs mean fewer spills, less waste, and more savings for both stores and manufacturers. On top of that, the dent is an economical engineering solution. Rather than using extra plastic to thicken the jug’s walls for durability, manufacturers add this cleverly placed indentation to reinforce the jug structurally. Much like the ridges on a cardboard box or the arches in architecture, the dent allows the jug to maintain strength without additional material.

It’s strong, efficient, and cost-effective—smart design on a budget. And in a surprising twist, that dent can sometimes serve as a subtle warning sign. When milk starts to spoil, bacterial activity produces gas, which builds pressure inside the jug. In such cases, the dent may begin to puff out or lose its shape. While this isn’t a foolproof spoilage detector, it can be an early visual cue that something might be off. So if the dent looks like it’s bulging or abnormal, you might want to give that milk a sniff before pouring it into your cereal. Now you might be wondering—why a circle? Why not a square or triangle? Circles are structurally ideal for handling pressure because they distribute stress evenly. There are no sharp corners to concentrate force, which makes the round shape perfect for a flexible, pressure-absorbing feature like this. They’re also easy to mold repeatedly in high-speed manufacturing processes, keeping costs down while maintaining consistency. While we’re on the subject of milk jug design, here are a few more interesting details you might not have noticed. The handle’s hollow center not only provides an easy grip, it reduces the amount of plastic used in production. Those tiny nubs at the base of the jug help it stay balanced on uneven shelves. Even the cap color can indicate fat content—blue for 2%, red for whole, and so on, depending on the brand. What might seem like a simple, disposable container is actually a masterpiece of form meeting function. From a sustainability standpoint, the dent helps reduce the amount of plastic needed in each jug, which translates into less waste, easier recycling, and lower transportation emissions due to lighter loads. So that small dent isn’t just a design feature—it’s an eco-conscious decision that benefits everyone. Next time you pour yourself a glass of milk, take a second to appreciate the circular dent doing its quiet work. It’s protecting your milk, keeping your fridge clean, helping the planet, and maybe even warning you of spoilage—all without saying a word. It’s the unsung hero of your morning routine, a tiny but mighty example of everyday engineering that often goes unnoticed. But now that you know the truth, maybe you’ll see that little dent in a whole new light.